| Precision Air Classifier | ||||||||||||||||||||||||||||||||||||||||||||||||||

+ Fluidized Bed Classifying Jet Mill + Precision Air Classifier + Classifying Impact Mill + Abrasive Powder Classifying Jet Mill/ Shaping + Bag Collector + Ultrafine Powder Processing Line

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

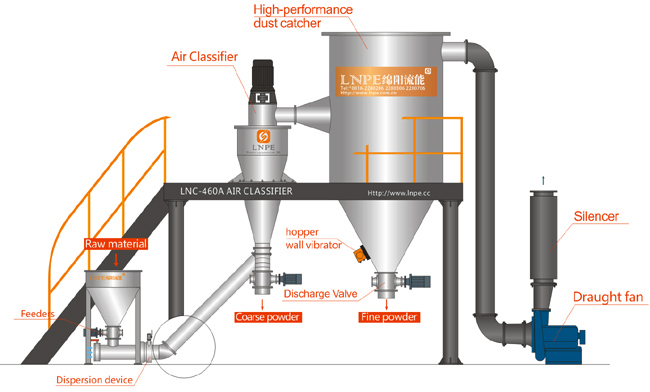

| Working principle: Depending on particles' size and density under dry-type for grading, it uses the centrifugal force produced by the fast rotation of grading rotator together with flow movement to perform classifying, the coarser particles above the grading rang is drove by centrifugal force will be swirled down along the container wall, and finer grains bring to the grinding zone. 1.Fluid dynamics software is developed by our independent R&D, calculated the perfect flow and ideal pressure distribution, is used for high efficiency grading, the grading rate is up to 70%~93%. 2.Dispersion device and turbulent device ensure high efficiency grading. 3.Aggregated powder is resolved by optimization structure . 4.The outer face end seal technology(unique technology) ensures no coarser particles leak. 5.Secondary air entry keeps the cleaning flow stability, greatly reduce the wear 6.Omniseal negative pressure operation, no contamination. |

||||||||||||||||||||||||||||||||||||||||||||||||||

| ■Application field | ||||||||||||||||||||||||||||||||||||||||||||||||||

Typical non-metallic mineral materials: calcium carbonate, kaolinite, talcum, carbon, calcite, wollastonite, barite, pyrophyllite etc. Tradition Chinese medicine’s ultra-fine process Typical material:pollen, hawthorn, pearl powder, Nimodipine, antibiotic, contrast agent, glossy ganoderma, Chinese galls, polygonum multiflorum thunb etc. |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||

| ■Main technical parameter | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||